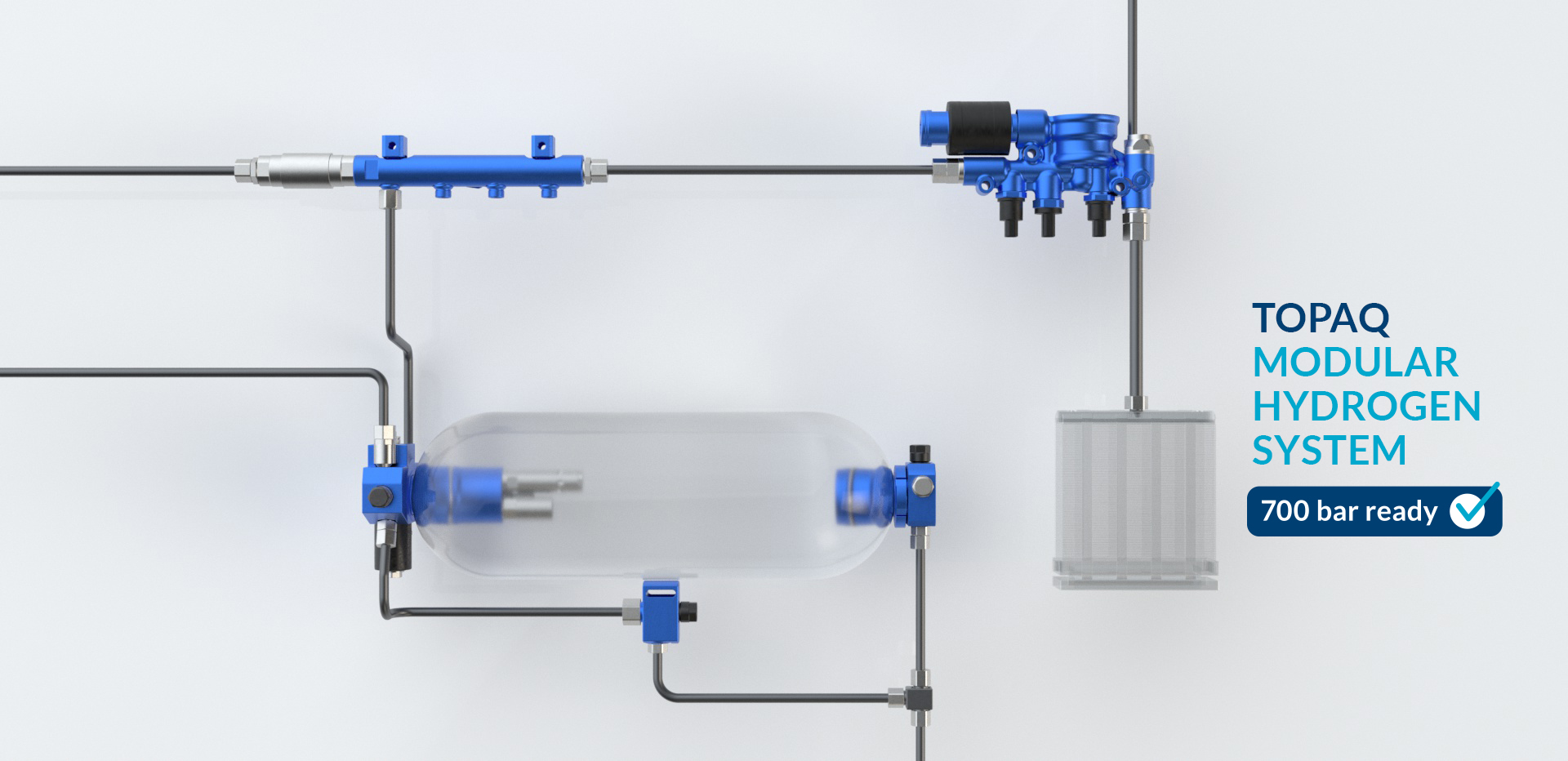

Our

modular

Hydrogen

System

Absolute customer-centricity enables us to offer unique H2 system architectures from a single source. In doing so, we lay out all the key components for transferring the hydrogen from the tank to the fuel cell or hydrogen combustion engine ourselves.

The On Tank Valve (OTV) 019391-A is used for the safe refuelling, de-fuelling and storage of gas in stationary and mobile H2 tanks.

Its optimised modular design enables the fulfilment of individual customer requirements while complying with relevant legal standards (EC79/2009 and EU406/2010).

| Installation space | Ø 177 mm |

| Height of OTV body + attachments | 185 mm |

| Material of OTV body | Aluminium |

| Seal types | Metal-on-metal, O-ring, PEEK |

| Operating temperature | -40 to +85 °C |

| Nominal operating pressure | 700 bar |

| Maximum allowable working pressure | 875 bar |

| Test pressure | 1050 bar |

Download

Data Sheet OTV

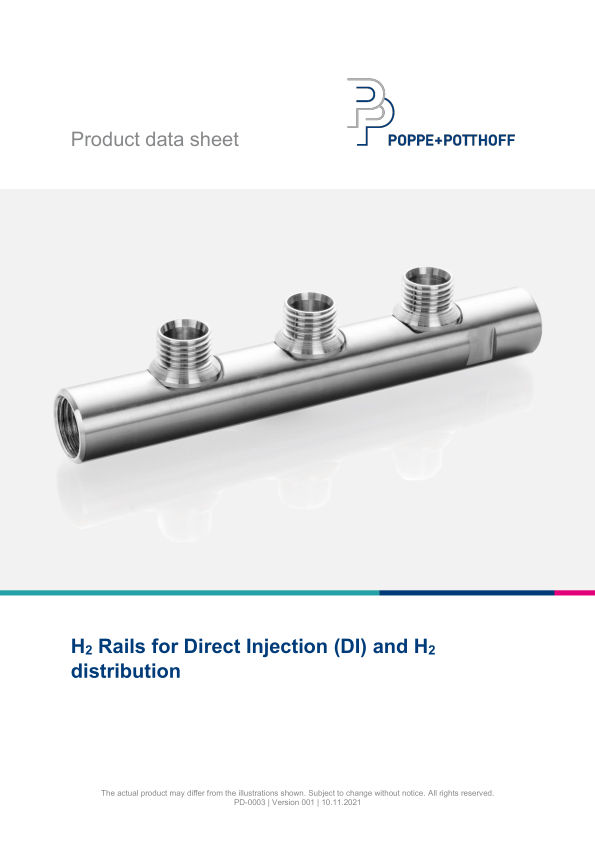

The H2 rails from P+P are used in direct injection processes to ensure a safe supply of hydrogen with uniform distribution to the injectors and to reduce pressure pulsations. They can also be used as distribution rails in storage and distribution systems of vehicles and stationary applications to distribute the hydrogen homogeneously to several storage tanks during the refuelling process.

The customer’s wishes and installation space requirements can be optimally met by varying the rail dimensions and the number and position of the pipe connections.

| Length of rail | for example 325 mm |

| Material | PPH2 |

| Type of seal | Metal-on-metal |

| Operating temperature | -40 bis +120 °C |

| Nominal operating pressure | up to 700 bar |

Download

Data Sheet Parallel Charging Unit

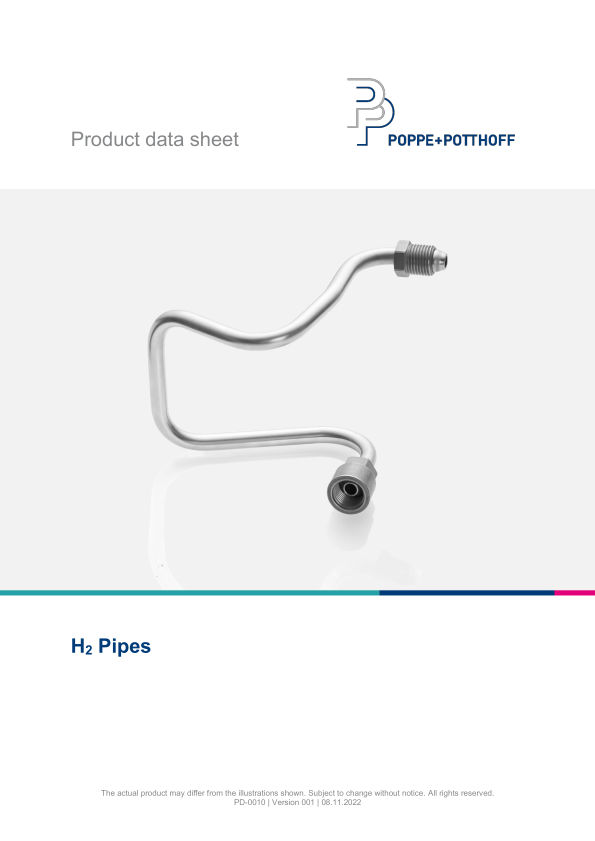

H2 PIPES are used to transfer hydrogen safely in mobile and stationary hydrogen applications.

A reliable reassembly is guaranteed with their certified metallic forming head connection.

Through the targeted variation of the pipe dimensions, it is possible to fulfil individual specifications and installation space requirements optimally.

| Length of pipe | for example 450 mm |

| Material | PPH2 |

| Type of seal | Metal- to-metal |

| Operating temperature | -40 bis +120 °C |

| Nominal operating pressure | up to 700 bar |

High Pressure

Regulation Unit

Our P+P-HIGH PRESSURE REGULATION UNIT can be used on all stationary and mobile H2 supply systems. Specially developed for mobile use on the fuel cell and the hydrogen combustion engine, it can also be used in many other applications such as electrolysers, hydrogen production or packaging plants for particularly constant pressure conditions due to its flexibility and application-specific adaptability.

With a low weight in-line design, the HPRU allows different sensor options for optimal control of the media flow with direct electronic influence on the control conditions.

Our solution offers an output pressure adjustable between 9 -16 bar with a control accuracy of at least 95 %. The possible mass flow per valve is given as 8 g/s. Parallel connection of several valves is possible to maximise throughput.

The thermal pressure relief device (TPRD)

016280-K is used to safeguard gas storage tanks in the event of a fire by ensuring rapid and spatially targeted degassing at elevated temperatures and preventing the tanks from bursting.

Due to an optimised design, the TPRD enables the fulfilment of individual customer requirements with the possibility to use it at different tank positions.

| Material | Aluminium, stainless steel, glass |

| Operating temperature | -40 bis +85 °C |

| Nominal operating pressure | 700 bar |

| Maximum allowable working pressure | 875 bar |

| Test pressure | 1050 bar |

| Leakage before bursting | 1200 bar |

Download

Data Sheet TPRD

The thermal pressure relief device (TPRD)

016280-K is used to safeguard gas storage tanks in the event of a fire by ensuring rapid and spatially targeted degassing at elevated temperatures and preventing the tanks from bursting.

Due to an optimised design, the TPRD enables the fulfilment of individual customer requirements with the possibility to use it at different tank positions.

| Material | Aluminium, stainless steel, glass |

| Operating temperature | -40 bis +85 °C |

| Nominal operating pressure | 700 bar |

| Maximum allowable working pressure | 875 bar |

| Test pressure | 1050 bar |

| Leakage before bursting | 1200 bar |

Download

Data Sheet TPRDDiverse

Application

Areas

TOPAQ offers one flexible solution for diverse hydrogen applications. For example, the modular design of the hydrogen supply system can be used in the on- and off-road area, in industry or for hydrogen storage (MEGC).

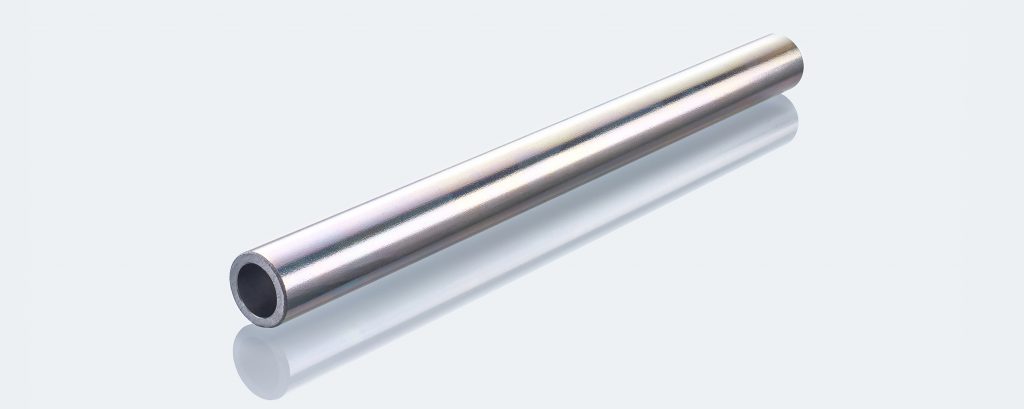

Material Expertise to save Weight and Costs

A wide range of components within the H2 propulsion system must have special properties and resistance to corrosion.

Our specially developed material, PPH2, is suitable for the production of H2 components and is approved for use in hydrogen applications within the scope of EU Regulation (EC) No.79/2009.

PPH2 enables the manufacturing of thinner-walled high pressure lines, therefore contributing to the reduction of CO2 emissions and saving materials (costs) and weight.

TOPAQ is a trademark of Poppe + Potthoff