-

Innovative test systems

for e-mobility

TEST BENCHES FOR

E-MOBILITY

Electromobility places high demands on a wide range of components. With specially developed test benches from Poppe + Potthoff Maschinenbau, we enable our customers to validate a wide range of components as early as the development stage.

Get to know our broad portfolio of innovative test systems!

Manufacturers can now precisely analyse their products with pressure and temperature cycling test benches as well as the functional test systems from Poppe + Potthoff Maschinenbau.

MORE ABOUT OUR TEST BENCHES FOR E-MOBILITY

TEST BENCHES FOR

E-MOBILITY

Media-carrying components, e.g., for cooling and heating systems, must endure extreme load changes and, at the same time, operate highly efficiently, especially in electric vehicles.

Function

test benches

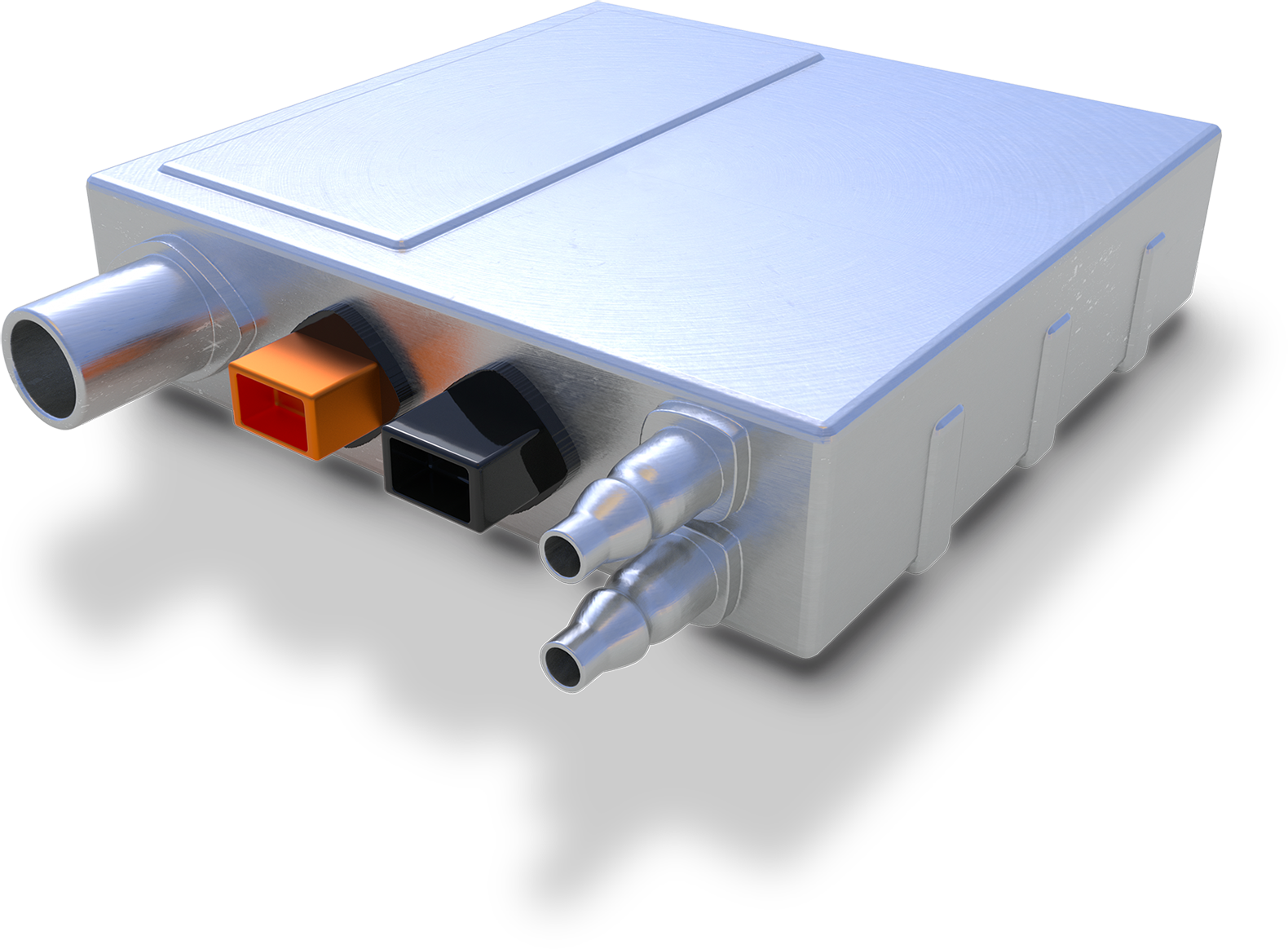

Functional test benches test heating and cooling units for e-mobility. During life cycle tests, performance as well as power consumption are evaluated to detect and eliminate weak points.

The test medium circulates at a freely controllable temperature of -40 °C to +100 °C. Optionally, the test can be performed in a climatic chamber at -40 °C to +140 °C to simulate changing ambient temperatures.

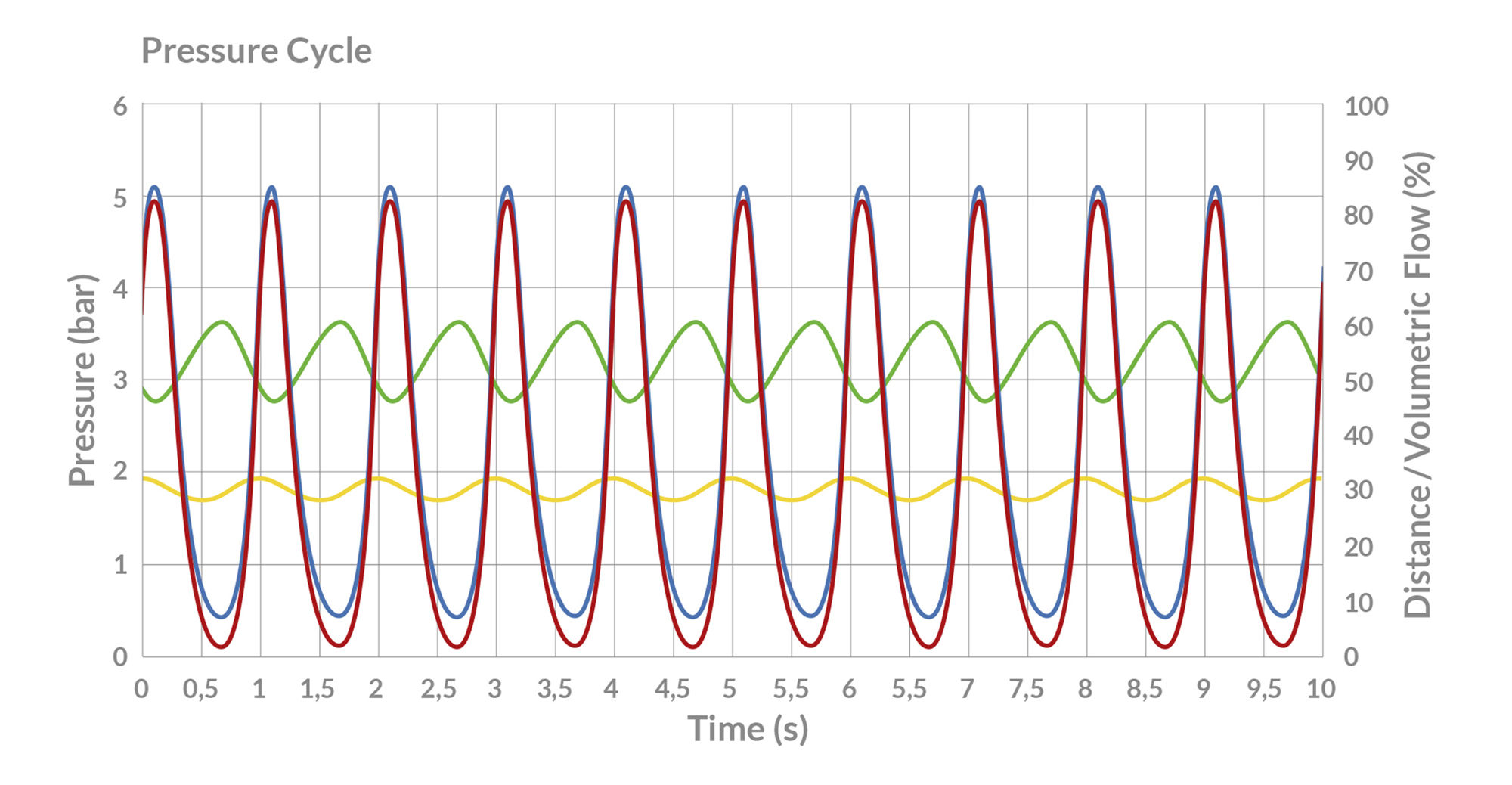

Pressure cycling

test stands

Our pressure cycling test rigs enable tests at temperature differences that are rare even for endurance tests on the Nürburgring race track, in the Siberian tundra or in the deserts of Africa.

For impulse testing followed by long-term pressure and burst testing, our systems offer two chambers in each of which up to ten test specimens can be tested simultaneously at an ambient temperature of -60°C to +180°C or room climate.

Burst pressure

test benches

In electric vehicles, media-carrying components are exposed to extreme conditions. The load-bearing capacity of pumps, pressure vessels, hose and pipe lines made of metal or plastic is verified with dynamic and statistical pressure tests.