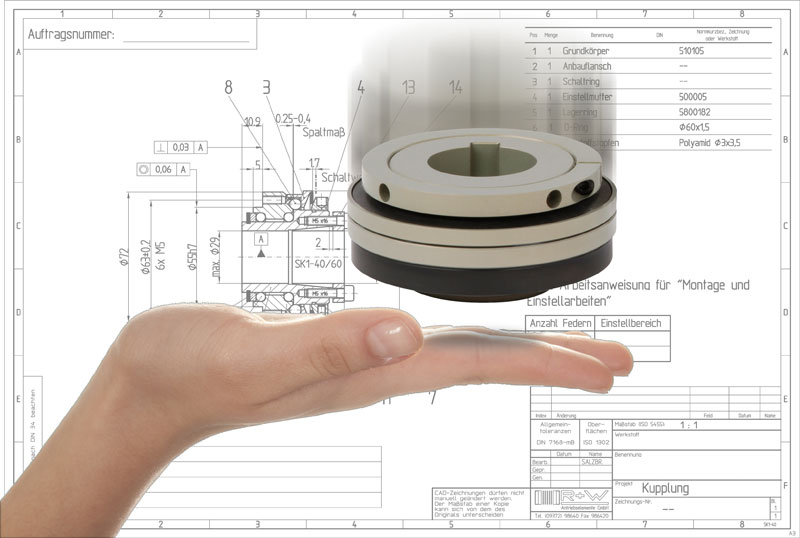

Lightweight coupling

Wörth/Werther (Germany), June 4, 2020

The Poppe + Potthoff subsidiary R+W has reduced the weight of its safety couplings by up to 60 percent with the TORQLIGHT SL series

Safe, durable, and light – these properties are particularly in demand in the aerospace industry, because every gram costs a lot of expensive energy during transport. This is why a weight-optimized safety coupling from R+W is in use on the international space station ISS. It ensures that there are no overloads when astronauts keep fit on the training equipment in weightlessness.

Also in more down-to-earth applications in mechanical engineering, robotics and automotive engineering, weight is playing an increasingly important role. Lightweight construction helps to reduce the mass moment of inertia and energy requirements. For electric vehicles, for example, R+W offers a light and robust safety coupling that prevents the gearbox from being damaged in the event of full braking.

The developers based their work on a proven coupling model from R+W, compressed the components and used special high-tech materials that enable cycle rates of up to 10,000 disengagements or more. The ball detent mechanism was also optimized. It enables precise torque limitation, increased by up to 50 percent, with switching times of a few milliseconds.

With the coupling series TORQLIGHT SL, R+W offers the market an extremely light, compact and high-precision torque limiting coupling. It is available in different versions and sizes for disengaging torques from 10 to 700 NM. The spring loaded ball detent mechanism is characterized by permanent precision and reaction times of 3-5 milliseconds. It thus ensures safety with ease.